Introduction:

Solvents, which are the key elements of many industries, are currently derived from fossil fuels. The usage of these solvents causes an increased risk to health and environment. Many solvents contain Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) which, in the presence of sunlight and nitrogen oxides (NOx) lead to the emission of ground level ozone and thus, contribute to ozone pollution.[1] VOCs also cause the green-house effect. Hence, it is necessary to minimize their usage or replace them with renewable/bio-derived solvents.

Solvents can be prepared from renewable sources to decrease the reliance on petroleum-based products, which are a limited resource. The solvents prepared from renewable sources such as agricultural crops or biomass are called bio-derived or bio-based, or simply, bio-solvents. These renewable solvents generate lower VOC emissions, are 100% biodegradable, easy to recycle, non-corrosive, non-carcinogenic, and non-ozone-depleting. These bio solvents are used in a number of industries such as paints & coatings, pharmaceuticals, adhesives, home & personal care, industrial & domestic cleaners, plastics & polymers, agrochemicals, food & beverage, printing inks, cosmetics, petrochemicals and fuels.

Sources of bio-based solvents:

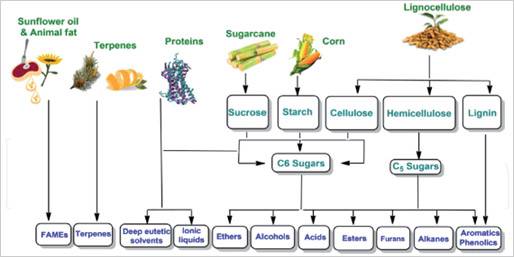

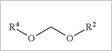

Natural sources that can be used for the production of bio-solvents include waste materials (agricultural, wood, and urban wastes, crop residues), forest products (wood, logging residues, trees, shrubs), energy crops (starch crops such as corn, wheat, and barley, sugar crops and grasses) and, aquatic biomass (Algae, water weed and water hyacinth). Biomass can be divided into three categories based on their chemical composition; namely, cellulosic biomass, starch and sugar-derived biomass (or edible biomass), and triglyceride-based biomass. A wide variety of solvents such as alcohols, ethers, acids, esters etc. are synthesized from different natural sources. A few examples of classes of bio-based solvents synthesized from biomass sources are shown in the figure below.[2]

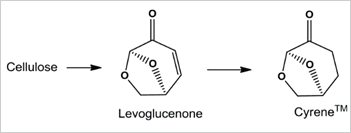

Cyrene is an alternative solvent to Dimethylformamide (DMF), N-Methyl-2-pyrrolidone (NMP) and DCM. Cyrene™ was awarded the ‘European Bio-based Chemical Innovation of the Year’ award in 2017 and the ‘Environmental Leader’s Top Product of the Year’ award in 2019, in recognition of its credentials as a safer, greener alternative to petroleum-based solvents that can also have superior performance.[11]

Cyrene is an alternative solvent to Dimethylformamide (DMF), N-Methyl-2-pyrrolidone (NMP) and DCM. Cyrene™ was awarded the ‘European Bio-based Chemical Innovation of the Year’ award in 2017 and the ‘Environmental Leader’s Top Product of the Year’ award in 2019, in recognition of its credentials as a safer, greener alternative to petroleum-based solvents that can also have superior performance.[11] Recently, in 2022, Circa partnered with Valmet for the targeted production of 1,100 tonnes of Cyrene™ by 2030, through the ReSolute project, by optimising the Furacell™ production process. The scale-up plant is situated in the Grand-Est Region (France).[17] Valmet is a developer and supplier of process technologies, automation, and services for the pulp, paper, and energy industries.

Recently, in 2022, Circa partnered with Valmet for the targeted production of 1,100 tonnes of Cyrene™ by 2030, through the ReSolute project, by optimising the Furacell™ production process. The scale-up plant is situated in the Grand-Est Region (France).[17] Valmet is a developer and supplier of process technologies, automation, and services for the pulp, paper, and energy industries. Green Biologics used their patented fermentation (US20150368678A1) process, using the Clostridium saccharoperbutylacetonicum microorganism to convert feedstocks into the bio-based n-butanol. SOLVONK4TM is composed primarily of butylal, which is a diether acetal for which n-butanol is used as reactant. About 550 SYSTEMK4 cleaning machines have already been installed in over 20 countries. In addition to the environmental benefits, it has a unique cleaning power and is economical.[22]

Green Biologics used their patented fermentation (US20150368678A1) process, using the Clostridium saccharoperbutylacetonicum microorganism to convert feedstocks into the bio-based n-butanol. SOLVONK4TM is composed primarily of butylal, which is a diether acetal for which n-butanol is used as reactant. About 550 SYSTEMK4 cleaning machines have already been installed in over 20 countries. In addition to the environmental benefits, it has a unique cleaning power and is economical.[22]